|

Advantages of plastics for optical equipment.

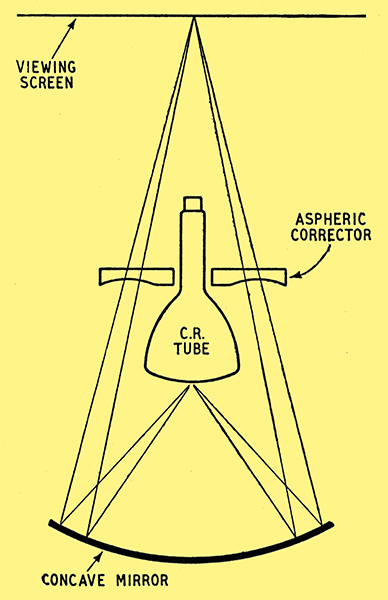

Layout of the Schmidt optical system for projecting television pictures on a screen.

There is no doubt that the attainment of larger television pictures must depend very largely on projection technique, if only because the convenient maximum in size for a directly-viewed cathode-ray tube has already been reached. The most widely used tube to-day has a screen diameter of 9 in and an overall length of about 18 in and produces a picture 7½ in by 6 in; 12 in tubes are used and are proportionately bigger in every way. Anything much larger than this becomes impracticable for home use.

It is an attractive idea to produce a small and very bright picture on a small tube and to project it optically on to a viewing screen. By optical magnification any required size of picture can be obtained and the physical dimensions of the apparatus can be kept within reasonable limits. Moreover, the picture can be obtained on a flat surface instead of the rounded end of the tube.

Projection television is by no means new and sets embodying this principle were on the market before the war. However, there have always been certain difficulties which have hitherto prevented it from becoming at all widely used. These have lain in the attainment of adequate brightness and definition.

The brightness required at the tube itself, of course, varies as the square of the linear dimension of the final picture and there is nothing that can be done about this. There is also a loss in the optical system as compared with direct viewing and it is here that serious difficulties have been encountered.

For efficiency an optical system of very large aperture is needed, but with the conventional glass lenses and mirrors a large aperture demands the use of spherical surfaces if the manufacturing cost is not to be prohibitive. Now spherical surfaces result in spherical aberration and a loss of definition and contrast in the final picture. As a result a compromise is adopted between aperture, aberration and cost and the loss of light is quite considerable.

During the war great strides were made in the development of plastic, instead of glass, lenses for optical equipment and this technique is now being applied to television projection. The great advantage of plastic over glass is that it becomes economically possible to adopt surfaces other than spherical and so a large aperture system free from aberration becomes possible. It is true that a suitable mould has to be made and that this is quite as difficult as making a glass lens of the same shape, but one mould can be used for many plastic lenses and with bulk production its proportionate cost per lens is small.

The technique of making plastic optical equipment was discussed recently by D Starkie in a paper read before the Institute of Physics in which he referred to the work of Imperial Chemical Industries. Two suitable materials are available and are known as Transpex 1 and 2; they are respectively especially pure grades of Perspex and polystyrene. They have refractive indexes of 1.49 and 1.59 and the softening temperature is 120° C.

For television purposes the Schmidt optical system is used as sketched in Fig. 1. Two models were shown at the lecture. One used a 2¼ in CRT with an 8 in diameter optical system giving a magnification of 8.5 times at a throw distance of 40 in. The other had a 3½in tube with a 14 in optical system and a magnification of 7.5 times at a throw distance of 69 in. The resolution is claimed to be adequate for a 1,000 line television system.

As shown in Fig. 1, the CRT on which the picture is formed faces a concave mirror. This is made of Transpex with a surface layer of aluminium deposited in a vacuum chamber. The aperture is f/0.75 and would in itself be sufficient to focus an enlarged picture on the viewing screen if it were not that it introduces spherical aberration. The effects of this are overcome the aspheric corrector plate mounted around the tube. It is this component of the system which would be so difficult to manufacture if glass were used.

|