|

How Circuit Designers and Operators can help the Manufacturer.

The M8082, M8083 and M8137 are examples of reliable or special quality valves.

While valve engineers can design a reliable valve entirely by calculation and special testing, the achievement of satisfactory performance is not a matter of engineering design only, for the valve must be mass produced and then be capable of operating under a variety of conditions. As a result there are two other factors apart from design that affect the performance: control of manufacturing limits (which, of course, is the responsibility of the maker), and the attitude of the user towards the application of reliable valves. It is the second one with which we are now concerned.

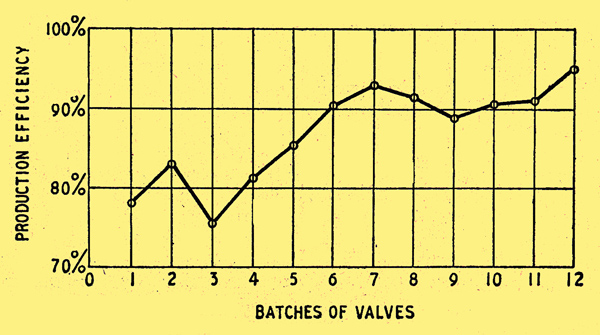

An examination of the distribution of electrical characteristics of any valve in production shows that it is always wider for the first period of production, and the effect shows up even when well-established existing designs are reintroduced. Also, it has been proved that high valve reliability can be secured only if there is a high yield on manufacture (known as a low production shrinkage). Such a state is achieved by uninterrupted production over a considerable period of time, when the familiarity of the individual operator with the job secures maximum skill and consistency. Consequently, the philosophy of making reliable valves is that it is essential to keep the number of individual types to an absolute minimum and the quantity of each of these types as large as possible, so that long and continuous manufacturing runs can be carried out.

Graph showing the increase in production efficiency with the number of batches of valves made in continuous manufacture.

An appeal must therefore be made to the circuit designer to do his best to confine himself to a short list of types, and to be prepared to use more valves of these types, if necessary, rather than use yet another type that may be more elegant technically.

When reliable valves have been used for reasonable periods in equipments, the valve maker will want to know how well the product is behaving in all of the special applications for which it has been designed and manufactured. No matter what the difficulties, this information must be obtained so that an accurate correlation can be maintained between field conditions and the many valve-testing machines used in the factory. It is appreciated that with equipment distributed all over the world, often in the hands of semi-trained operators, this requirement is not easy to meet, but it has been solved by the air lines in both Canada and the USA, and determined attempts are now being made in this country to see that the valve manufacturer is not hamstrung for lack of information.

This policy of user-manufacturer liaison has benefits for the user as well. Each batch of valves that is manufactured is carefully tested for the main mechanical and electrical requirements, and samples of the valves are always exhaustively checked to the point of destruction for certain of the special characteristics. While this is going on careful records are kept of the performance, and these are retained so that individual valves 'may be traced and their performance assessed. Criticisms or complaints from users can then be investigated with a very real probability of satisfaction for both parties.

Perhaps the most important thing of all is the user's attitude towards the application of reliable valves. Past experience in the commercial manufacture of valves has shown over and over again that conservative operation leads to longer life and less frequent catastrophic failure from such causes as low emission or gas. This is especially true of unusual applications where the valve is often required to do a job for which it is unsuited by reason of design or method of manufacture. It would be illogical to assume that the reliable valve will be better in this respect simply because it is designed to give less trouble under severe mechanical conditions. It cannot be emphasized too strongly that the valve is a willing little chap too ready to give his life in the service of his master-and is very often required to do so!

Whilst the main effort of both valve maker and user is directed at present towards the immediate problem of making existing equipments more reliable by using valves that are replacements of existing types, it is very important that the policy for the future is well defined.

The biggest stumbling block to the ultimate reliability of glass-based valves is the valve holder. The valve manufacturer has recognized the problems of incompatibility between valves and valve holders and has compromised by specifying the use of a wiring jig to centralize the socket contacts during circuit assembly and a pin-straightening jig for the valve pins before insertion into the valve holder.

Wiring jigs for B7G, B9A and B8A valve-holders.

Despite all this, considerable evidence has been obtained that semi-skilled personnel can cause a mechanical insertion loss of 3 per cent or greater, and whilst this can be reduced by careful training, the requirement of 1 percent failure in 1,000 hours (agreed as an objective definition of reliability) is easily swamped by this single possibility.

Because of the inevitability of some loss due to this, it is clear that for requirements demanding absolute reliability the valves will have flying leads and will be soldered into the circuit. The size of the envelope will be dependent on thee dissipation requirement, the sub-miniature being used for low-dissipation valves with the miniature and Noval types for better characteristics and higher dissipations.

Results of the present programme of work on reliable valves are likely to show that the valve is no longer the prime limiting factor to trouble-free performance of electronic equipment, and it is anticipated that the user will be turning to manufacturers of other circuit components for assurance of equal standards of reliability. This situation is already occurring with miniature potted circuits-the self-contained units including sub-miniature valves and components designed for ease of mass production and assembly.

In conclusion, it must be acknowledged that the user's attitude has up to the present been of real assistance in the design and early manufacture of the reliable valve. Considerable evidence has already been obtained from the Armed Services regarding the applications of the valves, and it is hoped that this trend will be continued when industrial equipment manufacturers begin to use them in quantity.

|