|

Valves have long been used in which the anode forms the outer coating in place of the usual glass or silica. Such valves lend themselves readily to water-cooling since the water can be applied directly to the anode. Such valves have been designated C.A.T. (cooled anode transmitters e.g. CAM3). Receiving valves, constructed on the same principle, have been developed by the Marconi-Osram organisation, and are called Catkins.

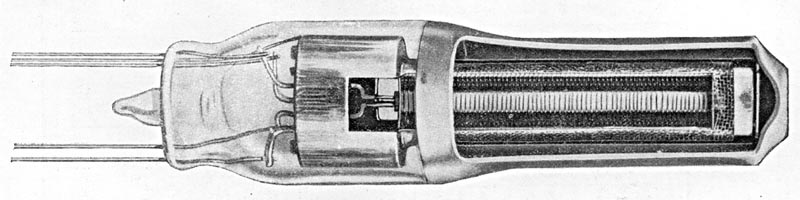

The construction of these valves is illustrated above. The various supporting wires are firmly held by a steel clamp which surrounds a mica insulator. The general assembly is held with precision by a mica spacing piece, and the whole valve forms a rigid unit which is much more effective for ensuring constancy and uniformity of characteristics. Moreover, the valve is almost unbreakable.

Dielectric losses due to the glass pinch in ordinary valves are reduced by using mica as an insulator, although it is true that the leads which pass through the glass ring at the base of this new valve are separated by glass, but these wires are as far apart as possible.

The absence of a glass bulb prevents the accumulation of unwanted potentials on the inside of the valve due to the accumulation of stray electrons; there is thus no tendency for hum to develop in mains receivers, or certain forms of back-coupling which can be traced to stray electric fields between the bulb and the leads. If the anode is to be screened (as it will usually be in the case of an HF valve), a tubular metal cover is provided.

When the anode is exposed, there is no risk of shock as the anode is given a generous coating of enamel. The fact that the anode is exposed to the air will result in a cooler working of both the anode and the grid.

The rigidity of the valve removes the common fault of microphony, which in its most objectionable form consists in the building-up of a howl due to the sound from the speaker causing vibration of the electrodes of a valve. In the Catkin construction, the valve is fixed in a rubber mounting; there is thus a double insurance against microphony. The valves are smaller in size than the glass equivalents.

An additional advantage of the Catkin is that there is no glass bulb which requires to be deprived of its occluded gas.

The most interesting feature of the valve from a technical point of view is the junction between the glass portion of the valve and the copper anode. To produce a gas-tight seal of this kind is a highly important development when applied to quantity production. In sealing the copper to the glass the parts are brought into contact while hot, the temperature being high enough to cause the glass to wet the metal. The metal in contact with the glass is made exceedingly thin, so thin in fact that the stresses in it when the glass cools are not sufficient to break it away from the metal. Such seals are stated to be very satisfactory, and are said to have been used from the temperatures of liquid air to that of molten glass without deterioration.

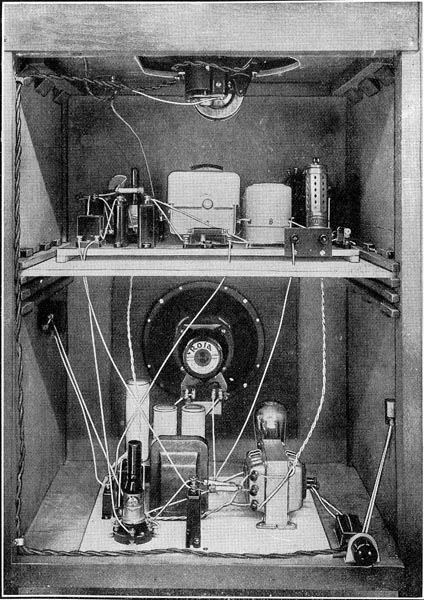

The picture above shows the inside of a 'Radiogram' of the period. The three catkin valves are easy to find, but it is interesting to see the technology and construction standards that existed in the early 1930's

Examples of Catkin valves in the museum are: MS4B, W30, MH4, MPT4 and N30.

|