|

Ahead of all competitors, Popular Wireless is able to give the first full details of the very latest development in radio technique - the Catkin valve. Made without any glass bulb at all, and with remarkable advantages of permanent electrode spacing and durability, this amazing new valve will shortly be available all over the country.

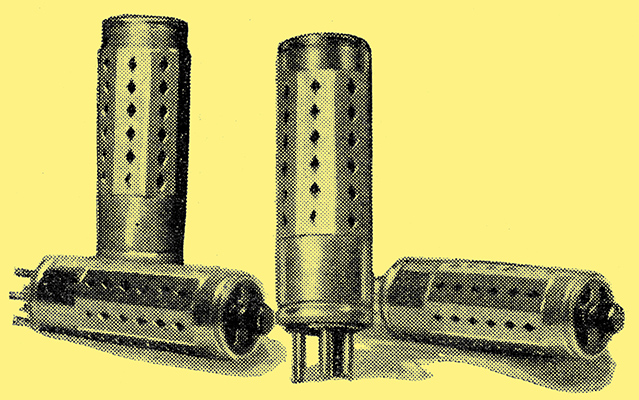

Instead of the familiar glass bulb Catkin valves have all-metal case. Their internal construction also is phenomenally robust, details of this being given in the accompanying exclusive article.

Popular Wireless again first - and with Catkins! What does it all mean?

It means that still another development has taken place in the valve world the far-reaching consequences of which may have a very important bearing upon the future technique of sets, design. It means that PW has again soared ahead of all competitors by providing its readers not only with an exclusive description of what must necessarily be regarded as one of the most remarkable valve developments for many years, but concurrently with complete constructional details of the first set ever to be published incorporating the new valves.

Not just an announcement, not merely a description of the new valve itself, but as much practical information as it would be possible to cram into any one issue is the substantiation for our claim to be first with the news.

And what news, too! Marconi and Osram - names that are household words - about to produce a range of valves in which the orthodox glass container is entirely dispensed with.

In view of the rapidity with which development has followed development in the valve world, and all in a matter of about two months, the reader might well pause to wonder where it is all going to end. Why worry! Of one thing you can definitely be, certain. Underlying all this amazing activity is the reassuring prospect of greatly increased efficiency with hitherto unequalled economy.

Made From Metal

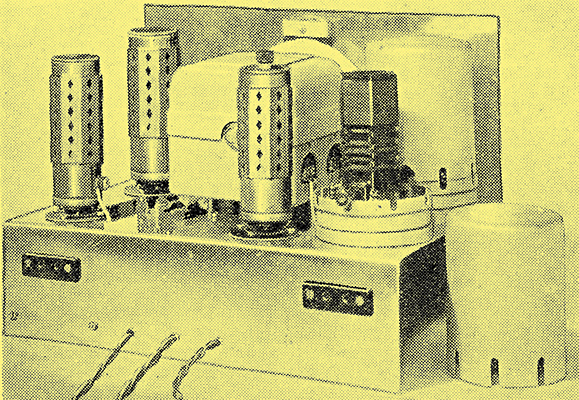

This is how the new valves look in the Catkin Three, the world's first all metal receiver.

New valves, new circuits, new standards. And with the advent of Catkins, it is no idle thought to suggest that the time may not be very far distant when glass-enclosed valves as we know them to-day become very different things! But that is looking a little too far ahead.

For the moment we can afford to neglect the future and concern ourselves only with the present. What, then, is a Catkin - perhaps we had better say a radio Catkin?

Superficially, it is - or looks like - an electrolytic capacitor case with a series of ornamental holes in it and with valve pins at the base in place of the usual fixing lugs. Perhaps the description is a little crude, yet it will serve to give you a mental picture of all that can be seen of this remarkable new valve.

Actually, it is a valve that is made almost entirely from metal. You can drop it; in fact you can treat it just as roughly as you like within reason, but it will still be every bit as efficient when you have finished with it! And that is only just the fringe of the story.

The Actual Anode

When valves were first thought of, the necessity of mounting the electrodes in a vacuum no doubt carried the minds of the designers to a parallel case - that of the electric lamp. Broadly speaking, the two processes were similar, and in consequence, since the desired degree of vacuum could be obtained from the use of a glass container, no thoughts of other methods even arose.

But efficient as modern valves are today, there are difficulties to be overcome consequent upon the use of a glass bulb, not from the point of view of a user so much as from that of a manufacturer.

For instance, to take just one obvious example, the efficiency of a valve may be upset very considerably unless all forms of extraneous gas are completely removed, and to do away with that possibility the interior of each glass bulb has to be scrupulously cleaned before it can be used.

One must be fair and admit that with modern valves trouble from this source is rare in the extreme, but that is only because the British manufacturers are so very thorough. The fact that it has been overcome in so far as the finished valve is concerned does not lessen the manufacturing difficulties. One has only to remember that the material is thin glass to appreciate the care that must be exercised.

In what one might justifiably refer to as the revolutionary principle of construction of the Catkin valve, the glass container is entirely dispensed with. The actual anode of the valve, which takes the form of a drawn copper cylinder, is the envelope in which the vacuum is contained.

Thus, in consequence of the convection currents in the air surrounding the outer side of the anode, the valve can be run much more coolly, and the chances of extraneous gasses being given off at the consequential lower temperatures are much more remote.

It is the shape of this anode that gives rise to the name Catkin, although the designation is not altogether unconnected with the larger types of transmitting valves known as the CAT class, in which somewhat similar principles are involved.

Fixed Electrodes

The interior assembly of the electrodes in a Catkin valve is carried out in a way which is bound to result in absolute rigidity. The other electrodes are held in their correct positions with respect to the anode by accurately stamped mica distance pieces, so that however the valve is knocked about, relative movement is practically impossible. In order further to ensure that no relative movement shall take place, mica distance pieces are also employed to locate the cathode centrally inside the grid.

The pinch through which the electrode support wires are brought out is interesting in as much as it is a drastic departure from standard practice. In place of the usual glass pinch, a piece of sheet metal is firmly pressed around the support wires over what appears to be an insulating collar of mica.

The platinum wires from the lower ends of the electrode supports are then melted into a circular glass collar and pass finally to the valve pins. This glass collar, incidentally, serves to seal off the vacuum.

Spaced Supports

One advantage of this method of construction would appear to lie in the fact that wider spacing of the electrode supports is possible, and inter-electrode capacities should in consequence be lower.

The only part of the valve which is visible to the eye, the glorified pepper-pot, is actually no part of the valve at all, unless one can call an electrostatic screen an essential part. That is the function that it fulfils, although it is also intended to serve as a protective cover for the valve envelope which, of course, is the anode. Without this protective cover, the valve would be getting down to the old 'peanut' valve dimensions.

As it is, its overall dimensions are not appreciably smaller than those of existing types, although the diameter is uniform throughout.

Radically Different Principles

The arrival of a new valve incorporating principles of construction so radically different from those of existing types naturally provides the technical mind with considerable food for thought. It is obviously much too premature at this stage to offer any sort of concrete suggestions as to the electrical potentialities of the new valve, but certain definite facts emerge from a cursory examination of the mechanical advantages.

For instance, the new valve is phenomenally robust, the significance of which is two-fold. In the first case, it will stand up to rough handling without the slightest risk of the electrical characteristics being impaired. That is definitely an advantage from the point of view of the user, but it is likely to affect the manufacturing side to an even greater extent.

The mechanical soundness of the principles involved Will no doubt lead to greater uniformity between valves of similar types, but over and above that the whole chain of events in the manufacture of the valve should be considerably simplified. In years to come, that fact alone should have far-reaching effects upon price levels.

Then again, the fact that the operating temperature of the valve is likely to be very much lower due to the 'air cooling' principles involved is definitely an advantage from the technical point of view. In addition to increasing the useful life of the valve, it should appreciably affect the overall efficiency of certain types, particularly on the output side of the set.

At the present time the output available from a power valve is to an extent limited by the rate at which heat can be got away from the surface of the anode. The principles of construction of the Catkin should provide scope for considerable improvement in this respect, since the question of heat dissipation is to an extent overcome. Who knows; it may ultimately lead to mains output from battery sets without push-pull!

Another advantage that occurs to the mind is that from our own investigations into the causes of microphonic troubles, it is at safe prediction that the phenomena will be entirely absent with the method of construction employed in Catkins.

As for the four that are being produced now, the characteristics will remain identical with those of the existing glass bulb types. In other words, it will be possible to replace valves of the types.mentioned above with Catkins of similar designation, as soon as they become generally available.

Types Available

The first four Catkin types are: VMS4, MS4B, MH4 & MPT4

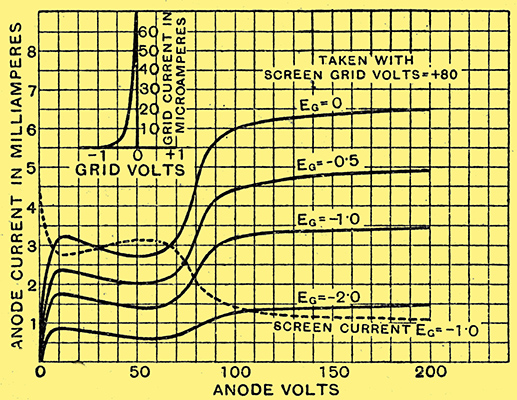

In the VMS4 Catkin, which is of the indirectly heated cathode type, the anode-grid leakage capacity is brought down to minute proportions.

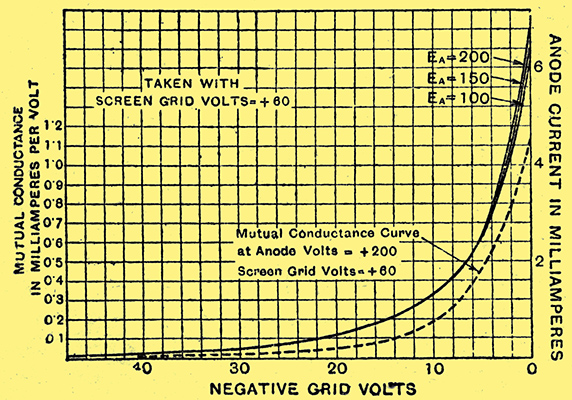

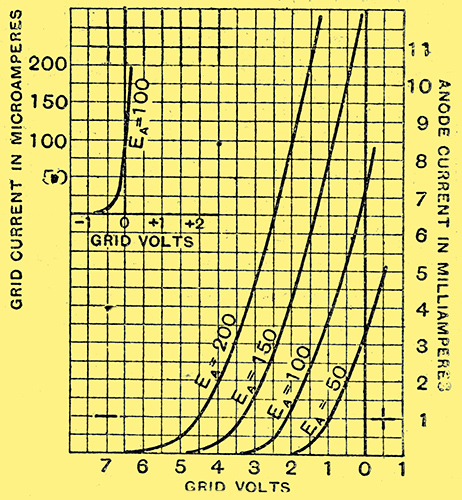

The curves of the MS4B Catkin an SG HF amplifier, with indirectly-heated cathode.

The AC Catkin of the MH4 type - which is to be known as the MH4 Catkin - has an amplification factor of 40, and mutual conductance oi 3.6.

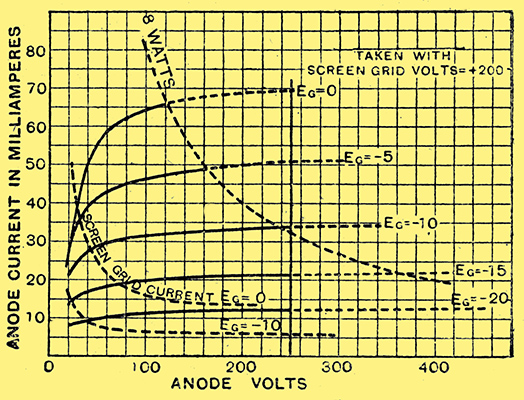

The impedance of the MPT4 Catkin is 33,000 Ω, the mutual conductance being 3.0 and the maximum anode dissipation 8 Watts.

|