|

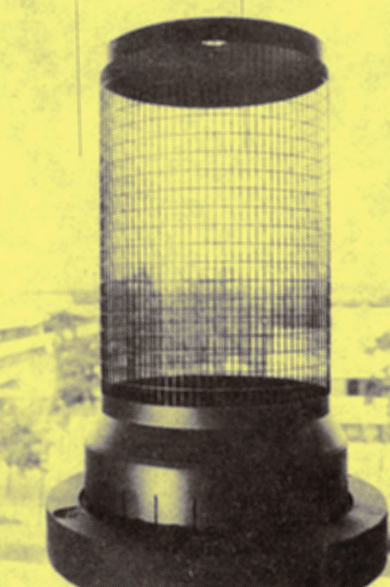

A Siemens pyrographite grid for a power tetrode. During normal working the valve may have to dissipate 100 kW or more, with the cathode and grid operating at a temperature of 2000 °K. The actual grid filaments are only a few tenths of a millimetre in diameter.

A form of graphite known as 'pyrographite', formed by the decomposition of methane at very high temperature (1900 °K) is being used by Siemens as the constructional material for grids in high power transmitting tetrodes. The process involves deposition of graphite on the surface of a cylinder, the final cutting of the grid structure being carried out by a laser beam.

Siemens say that the method yields grids of very smooth contour when compared with sandblasted control grids. Pyrographite has proved to have great dimensional stability in continuous operation and in addition graphite already exhibits neutral emission characteristics, emitting few electrons as a result of thermal excitation. Similarly, its low secondary emission properties make it preferable to wire or sheet metal grids, which have to be specially treated if their secondary emission features are to be controlled. Graphite remains free of grid currents even at high transmitter power.

At the moment these graphite grids are being used in tetrodes made by Siemens for short, medium and long wave transmissions. The smallest in the range is the RS2054 (100 kW) which has grid dimensions of 90 mm diameter by 170 mm high, while the largest has a continuous power rating of l,200 kW (the RS2084 SK). The grid developed for this model has dimensions of 21 cm diameter by 45 cm high.

The small external dimensions of these tetrodes, minimal stray capacitance and the advantages related to secondary emission performance combine to make them highly efficient. Although methane is being used by Siemens, other hydrocarbons may be employed for this process.

|