|

Mullard have recently introduced a new television picture tube - the AW47-10 - which represents a striking advance in picture-tube design. The AW47-10 incorporates two new Mullard developments: the 'twin-panel' safety faceplate and the 'short-neck' electrode assembly. The features ensure improved viewing and offer greater scope in the styling of receiver cabinets.

All manufacturers of television receivers in this country must provide a means of protection for the viewer in the event of a picture tube imploding. The British Standards Institution stipulates that the viewing screen of every television set must be completely covered by a safety guard.

In the past, this guard has taken the form of a separate screen fitted to the receiver cabinet. Now, however, with the introduction of the new Mullard twin-panel tube, the need for a separate guard has been removed. In the AW47-10, a specially designed transparent plastic shield is bonded directly to the glass faceplate to form a guard which is an integral part of the picture tube.

Twin-Panel Construction

The new Mullard twin-panel tube is fitted with an outer panel made of Diakon. The panel and the tube face-plate are bonded together by filling the space between them with a plasticised acrylic cement which is subsequently polymerised by ultra-violet irradiation.

The Diakon guard is carefully moulded in the shape of the faceplate so that the viewing surface of the guard has the same contours as the faceplate of the picture tube. Great care is taken when the cement is being introduced between the panel and faceplate to ensure that bubbles do not form, and sufficient cement is introduced to compensate for the shrinking which takes place during hardening.

Short Neck Construction

The AW47-10 has a rectangular screen with a 19-inch diagonal, and a deflection angle of 110°. Electrostatic focusing is used, and the focusing lens is of the 'uni-potential' type - that is, the two outer grids of the three-grid lens are at the same potential. In the new tube, the metal backing in the centre of the screen is sufficiently thick to prevent the heavy negative ions issuing from the cathode from penetrating to the phosphor. 'Ion burn' is thus prevented in the AW47-10 without the need for an ion trap.

The design of the electrode structure of the gun in the AW47-10 is such that a very short gun has been achieved. In addition to this, the sealing pip at the base of the gun is very small, so that the total length of the tube neck is only 110 mm.

Features of the AW47-10 Tube

The most striking feature of the new twin-panel tube is that receivers can now be made without a separate implosion guard. The consequences of this are that the viewer is presented with improved picture quality, and the receiver manufacturer is offered a wider scope in designing receiver cabinets. Other significant advantages accrue from the superior electrical properties of the short-neck construction.

Reduced Reflections

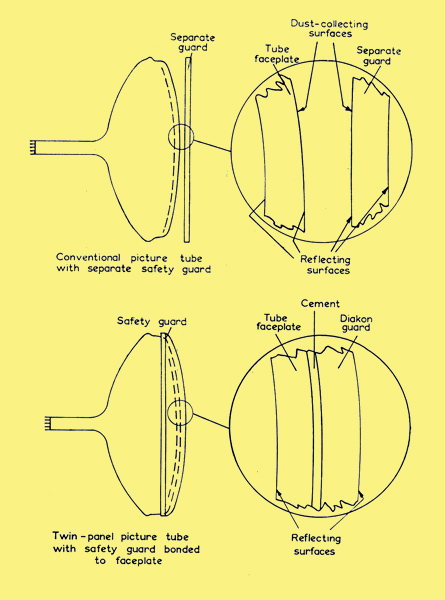

Fig. 1 - Indication of possible reflecting surfaces with conventional tubes requiring separate safety guard, and twin-panel tube.

In conventional television receivers, the picture is viewed through a safety window fitted in front of the picture tube. The viewer is thus confronted with four possible reflecting surfaces, two on the picture-tube faceplate, and two on the safety guard (See Fig. 1). The irritation caused by reflections of external light is well known. Reflection of light emanating from the fluorescent screen within the picture-tube produces a halo around any object in the picture, thus reducing the contrast between light and dark objects.

In twin-panel tubes, the Diakon, cement and glass have very similar optical properties, so that the combined faceplate and safety guard act as a single layer of material. The viewer is there- fore presented with only two possible reflecting surfaces (See Fig. 1). Both internal and external reflections are thus reduced to a minimum, and the picture contrast is consequently improved considerably.

Tinting

Light and dark in a television picture correspond to greater or lesser degrees of fluorescence at the screen. Black occurs when the electron beam is cut off and no fluorescence occurs, so that What is seen as black is actually the colour of the screen when the set is switched off. Degrees of lightness are measured against this 'black level'. Hence the contrast obtainable between black and. white depends on the basic colour of the viewing screen.

To increase this contrast, the viewing screen is normally tinted to give a dark 'black level'. This tinting reduces the brightness of the picture, but a compromise can be effected between good contrast and acceptable brightness. As it is impracticable to introduce all the tinting necessary into the glass from which the picture tube is made, it is necessary in conventional receivers to apply the tinting to the safety guard. With Mullard twin-panel tubes, however, tinting is applied to the Diakon panel, so that optimum contrast is an inherent property.

No Dust Accumulation

An aspect of conventional television receivers which is troublesome to the receiver manufacturer and viewer alike is the accumulation of dust in the space between the tube faceplate and the safety guard. The manufacturer is set the task of trying to provide a dust- proof seal around the space, and the viewer is confronted with a picture which is increasingly marred by the dust that inevitably penetrates to this space and collects on the surfaces surrounding it.

With the new Mullard tube, the twin-panel construction with guard and face-plate cemented together provides the perfect solution to the problem-there simply is no space in which the dust can gather.

Wider Viewing Angle

Present-day glass technology enables the bulb of the AW47-10 to be produced with an extremely flat and near-rectangular faceplate. Since the con-tours of the Diakon safety guard follow closely those of the faceplate, an almost flat picture is presented which can be viewed obliquely without much distortion occurring.

Better Spot Quality

Despite the variation in beam length which occurs in the AW47-10 as the electron beam scans the nearly-flat screen, the uni-potential focusing lens used ensures that the beam is focused on the screen at all deflection angles. This absence of deflection de-focusing leads to good spot quality over the entire screen.

Since an ion trap is not required with the AW47-10, interaction between an ion-trap magnet and the magnetic fields of the deflection coils is avoided. Consequently, an improvement in spot quality compared with earlier tubes requiring ion traps results, and of course, any need for adjustments to the ion-trap magnet during servicing is eliminated.

Smaller Cabinets

In conventional television receivers, the style of the cabinet is set to a large extent by the need to provide a safety window between the viewer and the picture tube. Use of the AW47-10, in which the safety window is a built-in feature, offers the cabinet designer greater freedom in styling.

Elimination of the space between the faceplate and safety guard when using the AW47-10 makes possible a significant reduction in cabinet depth. In addition to this, the short-neck construction of the new tube contributes further to the reduction. The total saving possible with the AW47-10 can be as much as three inches compared with conventional 19 inch, 110° picture tubes. In view of the slender lines already attainable in cabinets using a separate safety window, this reduction of three inches in depth represents a most noteworthy advance.

Coupled with the reduction in cabinet dimensions is the reduction in weight afforded by the adoption of the twin-panel tube. A receiver using the AW47-10 will weigh up to four pounds less than one which possesses a separate glass safety window. The savings in cabinet depth and weight resulting from the twin-panel construction are important features in the progression toward portability.

Mounting

The Diakon guard of the twin-panel tube is designed with lugs at each corner to facilitate mounting in the cabinet. Clamps fitted to straddle these lugs will secure the tube to the cabinet. The strength of the plastic lugs is such that the deflection coils can be placed directly on the tube without additional support.

Care should be taken in mounting the AW47-10 to ensure that the clamps bear on as great an area of the lugs as possible. As well as securing the tube firmly to the cabinet, the large bearing surface will produce the maximum safety factor. The method of clamping should give an evenly distributed pressure over the bearing surfaces. In particular clamping should not give rise to areas of localised high pressure. The Diakon panel should not be allowed to come into contact with any sharp edges.

Testing the Twin-Panel Construction

The AW47-10 is subject to the standard series of tests carried out on all types of picture tube produced by Mullard. Because of the novel feature of this tube, however, additional tests are required to establish the quality and durability of the twin-panel construction.

Protection Against Implosion

The chances of a picture tube imploding in a television receiver are extremely small, about one in a hundred thousand. However, because of the high energy stored in the glass envelope of the evacuated bulb, it is necessary to safeguard against even this small chance, and to provide the viewer with complete protection against implosion. The criterion of safety stipulated in this country is that the picture tube must be shielded and that, in the event of an implosion, no glass shall be thrown forward of the guard.

To establish that complete protection is provided by the twin-panel construction, exhaustive tests have been carried out by Mullard on the AW47-10. The tests used simulate closely the conditions that occur during an implosion. In one test, a heavy weight is dropped onto a metal pin held in contact with the junction of the tube face and cone. This test causes conventional tubes to shatter completely, but with the AW47-10 no violent breakage occurred. The most frequent result was for a hole to be punched into the tube envelope. In the other cases, the glass cone broke, but with little violence. In no case was any glass projected forward of the tube.

In another test, spontaneous implosion is simulated by creating a rapid change in temperature over a small area of the cone of the tube. Again, with conventional tubes, this test always produces an implosion whereas none of the twin-panel tubes imploded. The glass faceplates and cones cracked, thus allowing the vacuum to collapse slowly, but the Diakon guards were not damaged in any way.

The strength of the Diakon panel was further established by studying the effect of direct blows on the panel. In the test used, a hardened-steel ball suspended by a length of wire is allowed to swing against the panel and the blows repeated until the tube breaks or cracks. In most cases, the necks of the tube eventually broke, but the numbers of blows required to cause this varied considerably. In three-quarters of the tests performed, the only damage suffered by the panel consisted of a fine crazing in the region of the impact. In the remainder, a crack two to three inches long appeared. In no case was glass thrown forward.

Climatic Tests

Samples of AW47-10 were subjected to a series of temperature and humidity tests, and were examined during and after the tests for fracture, delamination, sandwich blemishes, discolouration, and so on. If the results of these tests were satisfactory, the tubes underwent an implosion test.

On all AW47-10 examined, the results of the climatic tests and the subsequent implosion tests were satisfactory.

Creep Test

To establish that there will be no movement of the tube relative to the Diakon panel, some AW47-10 were mounted in a television cabinet by means of the four securing lugs, and loaded with a weight equivalent to about twice the weight of deflection coils. The receivers were then stored for two months at 40°C. Examination showed that there was no detectable movement, and subsequent implosion testing proved to be satisfactory.

Ultra-violet and Solar Radiation Test

Samples of AW47-10 were exposed to a battery of incandescent lamps to test the effects of ultra-violet and solar radiation on the Diakon guard and the cement. After two months of testing, no discolouration was observed, and subsequent implosion tests proved to be satisfactory.

Aspects of Servicing

Tube Replacement

A receiver using an AW47-10 will not have a separate implosion guard incorporated in the cabinet. Under no circumstances should a tube intended for use in conjunction with a separate implosion guard be used as a replacement for the AW47-10.

When mounting the tube, the clamps provided in the cabinet should be used. Under no circumstances should holes be drilled in the securing lugs of the AW47-10.

Cleaning

If the Diakon guard of an AW47-10 becomes stained, it should be cleaned by washing with soap and warm water, using soft clean cloth or cotton Wool. Soda and other alkalis may be added to the water to remove grease, but these are not essential. Organic cleaning agents such as benzene, turpentine and paint removers must not be used, since they attack Diakon.

Because of the high resistivity of Diakon, an electrostatic charge is built up when the screen is rubbed with a dry cloth. Treating the surface with No. 3 Perspex polish will prevent this development of static charge, and thus eliminate or reduce the collection of dust on the outer face of the guard.

Handling

Although the AW47-10 is much more robust than a conventional picture tube, it is still inherently fragile, and should be treated accordingly. All the precautions taken when handling conventional tubes should also be taken with the AW47-10: mechanical shocks should be avoided; tubes should always be stored in their original packings; tubes should not be lifted by their necks.

As with conventional tubes, persons handling twin-panel tubes must be instructed to wear protective glasses and gloves as a precaution against injury in the event of breakage. While the twin-panel construction will safeguard a viewer in front of the receiver if a breakage occurs, it will not necessarily give protection to a person immediately behind a tube which is not enclosed in a cabinet.

Selling Points of the AW47-10

The benefits resulting from the use of the new Mullard 19-inch 'Radiant-Screen' twin-panel, short-neck picture tube can be summarised as follows:

- Complete freedom from dust between the safety guard and tube faceplate.

- Improved picture contrast.

- Improved spot quality.

- Wider acceptable viewing angle.

- Slimmer cabinets.

- Lighter receivers.

The electrical characteristics of the short-neck construction and the optical and physical advantages of the twin-panel technique combine in the new tube to make the AW47-10 an outstanding advance in picture-tube design and customer satisfaction.

Fig. 2 - Twin-panel tube, type AW47-10.

|