|

Electron Emission

But how is it that electrons can be made to move through a vacuum? It begins with the emission of electrons from a material, which occurs when the electrons have gained sufficient energy to escape from the forces binding them to the material. There are several ways in which this can happen, as follows:

- Thermionic emission

- Photo-emission

- Secondary emission

- Field emission

Of these it is the first, thermionic emission. that is of primary interest in understanding how valves work.

Thermionic Emission

Conduction with in a conducting material consists of the movement of electrons. Electrons are only available for conduction when they acquire sufficient energy to leave the parent atoms. In good conductors the amount of energy required for conduction is relatively small. If the amount of energy applied to the conductor is raised to a sufficiently high level some electrons do more than leave their parent atoms; they leave the surface of the material itself. What is a likely source of this energy? The answer is heat. This can be generated relatively easily for this purpose, as will be seen. When the electrons leave the conductor, several events can or will occur.

- Since the conductor has lost electrons, it becomes positively charged there must, therefore, be a force of attraction between the escaped electrons and the conductor itself. It is possible to anticipate from this that the electrons will be attracted back towards the conductor. This is a very important point.

- Electrons which have already escaped from the conductor form a negative 'space charge' which tends to repel any further electrons that try to leave the conductor.

- lf the heated conductor is surrounded by a gas or even just air, any electrons emitted are only able to travel a very short distance before a collision with a gas molecule takes place. This slows down the electron and deflects it from its original path. Such an action is normally undesirable in valves. For this reason, the valve 'envelope' (the glass tube or container itself) is evacuated by pumping during manufacture.

Paragraphs (a) and (b) lead to the following behaviour:

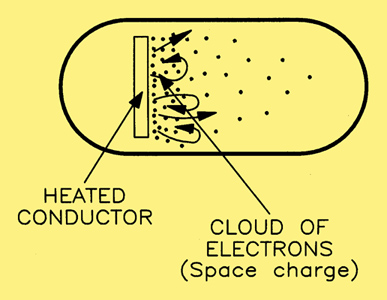

Electrons are emitted from the conductor's surface at a rate dependent upon the temperature of the conductor. Once they have been emitted they experience a force of attraction drawing them back to the conductor. They will eventually return there but, since emission is a continuous process, more electrons will leave the conductor to take their place. Thus, at any time, there will be a more or less constant cloud of electrons adjacent to the conductor's surface. This cloud is termed the 'space charge' (as mentioned earlier), and the effect is illustrated below.

The space charge around a heated conductor; electrons are continually emitted from and return to the conductor's surface.

The ease with which an electron may escape from a material is expressed in terms of what is called the 'work function. of the material. This is the energy, measured in electron-volts (eV), that an electron must possess before it is able to escape from that material. For the record: 1 eV = 1.6 x 10^-19 Joules. Values of the work function, in eV, for various materials are: Caesium 1.75, Copper 4.2, Mercury 4.2, Tungsten 4.5 & Platinum 6.15.

Generally, those materials with low values of the work function would have melted by the time that they had attained the temperature at which significant emission had occurred. But one material that does not do so is tungsten. This gives good emission at 2,300 to 2,500°C, and melts at 3,380°C. However, a valve with a pure tungsten emitter would, and did, glow rather like an incandescent lamp. This was characteristic of early valves e.g. Fleming, but modern valves have been developed in which the tungsten surface has been coated with an oxide such as that of barium or strontium, that allows efficient emission of electrons at much lower temperatures, mere 700°C.

Construction of Filaments and Cathodes

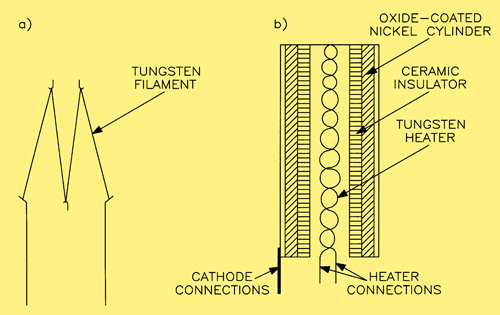

The emitting conductor is heated electrically, as one would suspect, by passing a current through a filament of wire. This filament may either emit the electrons directly (in which case the device is known as a directly heated valve) or it may be placed inside a tubular 'cathode' which emits the electrons (in which case we talk about indirectly heated valves), The two types are illustrated below.

Construction of (a) directly heated filament and (b) indirectly heated cathode.

The directly heated type was employed for small battery powered valves, as in portable 1940's wireless sets for instance, the filament current being DC. The indirectly heated cathode is the standard type for mains powered valves, where the supply is AC, usually 6.3V or 12.6V, except in TV practice where a variety of heater voltages is possible. From the fact that the heater current required for even small signal valves is about 300 mA for 6.3V operation and 150mA for 12.6V operation, it is obvious that the heater alone dissipates almost 2 W of power! Since the heater is the most likely point of failure in a valve (having an average life of about 2,000 to 3,000 hours), it is then also obvious why the transistor, which requires no heater power, is a more efficient and reliable device.

|