|

The pictures in this article come from the BVWS DVD of the 1950s Mullard film.

The base is made from a short length of hard glass and three different types of wire. The pins are formed on a specialist machine that cuts the pin, seal and lead wire to length and bonds them together. Its output was, in the 1950s film, small cups of finished pins delivered on a circular output section.

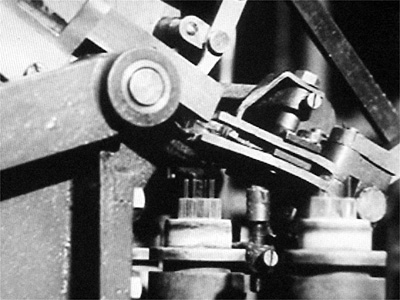

The pins in their cups were taken by the operator and placed in the base making machine. Here the pins were automatically fed in to the machine nine at a time and placed in a jig in their correct positions around the circumference of a circle.

Rings of glass sitting over pins ready for base forming.

The short glass tube sections were fed into the process such that the ring of glass sat on top of the circle of pins.

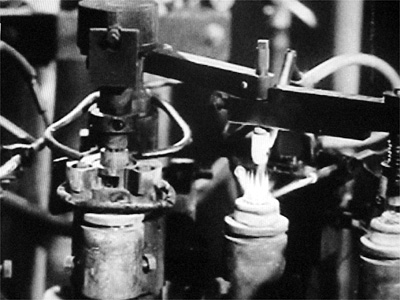

Gas flames play down on the glass ring and the softened glass being presssed against the pins to form the base.

The machine was equipped with many stations that passed in turn in front of the gas heating jets and pressure moulding heads.

After the bases came off the base making machine an operator would manually process them through two further stages. The first process was to hand feed the base into a cutting machine that trimmed the electrode wires to length. The second hand operation was to insert the base into a second machine that bent the wires to the right spacial positions ready for final assembly with the electrodes.

|