|

The pictures in this article come from the BVWS DVD of the 1950s Mullard film.

The flow of electrons from the cathode to the anode is influenced by the grids. These need to be made from materials that can withstand high temperatures without distorting and do not readily emit electrons when hot. Specialist grids have been made from Copper and even Gold Plated but the most typical grid construction was the use of Molybdenum wire on stout Molybdenum support rods.

The effect of the grid depends on its proximity to the cathode, the openness of its windings, and the properties of its materials.

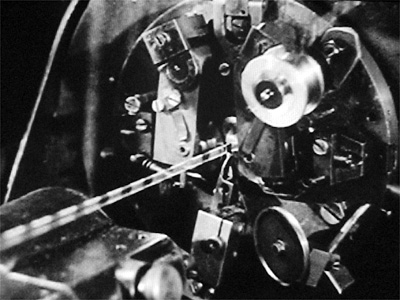

Grid winding machine - general view

The grids are made in long lengths on the grid winding machines. The drum spins and the support rods are fed through from the back of the production head.

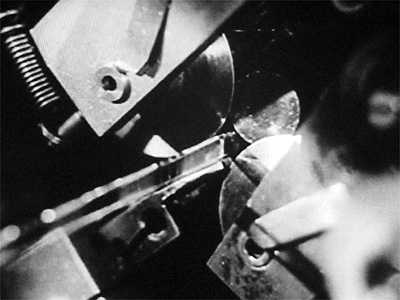

Grid winding machine - close-up

In the close-up view of the winding head the notching wheels can be seen. The process of cutting the notch, filling the depression with thin wire and then closing the notch with the peening roller all takes place at high speed as the head revolves. The rate of feed of the support rods controls the winding pitch and allows for greatly increased spacing to denote the inter grid space.

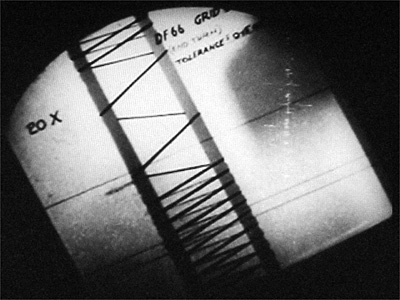

Projection of enlarged grid onto ground glass screen

The operator cutting the long lengths of grids to individual valve grids can see what is being done on a ground glass screen that carries a projected image of the grid magnified some 20 times.

|