|

Click the picture for the lady in the valve

Capt. Stanley Mullard worked for the Admiralty during the Great War, working on the design of transmitting valves. He was, therefore, well placed to enter the post war manufacturing industry with the knowledge that he had gained.

Joining the Z Electric Lamp Co. in 1919, he rapidly rose to the position of Managing Director. The Z Electric Lamp Co., operating from Southfields (London), made both receiving and transmitting valves for the Admiralty, Royal Air Force, The General Post Office and the War Office. These devices were sold under the brand name of S R Mullard.

He moved to form the Mullard Radio Valve Co. Ltd in 1920. This had significant financial backing from the Radio Communication Co. Ltd. Their interest being in having a competitor to the Marconi monopoly within marine radio.

Mullard's break from the Z Electric Lamp Co. led to the demise of that company. The premises were used by Mullard for his manufacturing requirements while his new plant was being prepared in Hammersmith (London).

Mullard's first ventures were variations of the 'R' type valve as well as transmitting valves. The business grew and in 1923 transferred to Balham in South London.

One of the bays of the valve exhausting department at Balham April, 1924.

The formation of the BBC consortium in 1922 and the commencement of broadcasting further fueled the growth of his business. The demands for addition capital were such that he sought external finance. He also needed additional technical resources, this twin need led to him selling half of his shares to the Dutch Philips company.

With Philips resources Mullard introduced the PM (Philips-Mullard) low-consumption valves using Barium-coated filaments manufactured by the 'azide' process pioneered by Philips on the Continent. Initial Mullard 'production' involved re-labelling imported Philips valves. The first British-made types (1926) were the PM3 and PM4.

Having invested heavily in the azide process, Mullard continued to use it for several years after their competitors had switched almost entirely to superior oxide coating processes. One conspicuous feature of the Mullard form of the azide process was heavy internal blackening of the glass bulb (e.g. PM22). This was OK while competitors' valves were equally black (although some used a magnesium pre-getter to make the glass look silvery rather than black), but when competitors started to extol the virtues of their 'clean' oxide-process valves, Philips-Mullard realised that something had to be done. The answer was brilliant gold paint! (e.g. PM12A). This became a characteristic feature of Mullard valves until they had got their own oxide processes sorted and left off the gold paint in order to show that their valves were clean too (e.g. PM12A). The extent to which the paint also provided an efficient electrostatic shield is not clear. Mullard seem to have used different grades of paint, sometimes but not always 'earthed' to cathode or to a filament pin.

The collaboration with Philips further grew the business but introduced tensions because military contracts and foreign ownership did not mix. In spite of this Mullard sold the rest of his shares to Philips in 1927. The non British ownership of the company was not generally made known and the Mullard name remained the trade mark for decades to come.

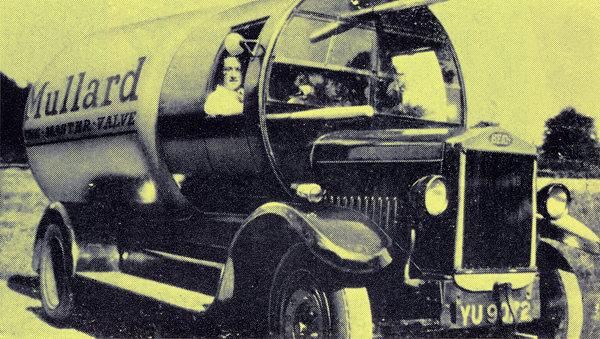

In the 1930s Mullard had publicity vehicles made in the shape of a valve. The picture below is of a model of such a vehicle.

Photograph of an actual vehicle from the early 1930's.

During WW2 the main factory complex at Mitcham in Surrey was hit by a V1 flying bomb. This happened on the 19th June 1944 and valve production was halted for a month. The loss of production was half a million valves.

As UK market leader in valve production in the 1950s Mullard produced promotional films and a presentation boxed set of components celebrating the very successful EF80. We have the EF80 boxed set.

Research by Per Olofsson via contact with the Community Historian/Librarian at the Central Library in Blackburn has revealed further details of Stanley Mullard. The company that carried his name had factories in Blackburn and the Blackburn records show that Stanley Mullard died in 1979 at the age of 95.

His life encompassed all the major developments in the valve era and he even witnessed the introduction of home computers and the triumph of the transistor over the valve.

Mullard Valves with Yellow Lettering

The 50th anniversary of the founding of Mullard Ltd. fell in 1969 and the company wanted to celebrate this milestone in some way on its valves.

In the 1930's with external zinc paint screening, Mullard used a distinctive gold paint before the introduction of the Red E Series in 1938 and thoughts turned to using a gold paint to mark the golden anniversary of the founding of the company. Investigations showed that this was impractical and an alternative was sought. The result was the yellow paint on Mullard valves in place of the standard white paint.

Yellow lettering was used for just the year following the date of the 50th anniversary. Valves returned to using the standard white lettering thereafter. However, in 1975 a drum of the yellow paint was found at the Blackburn factory and rather than waste it, production valves once more had yellow lettering until the drum was exhausted.

The new style logo first appeared in 1970.

The following is taken from Industry Notebook in the January 1974 edition of Practical Electronics.

As an example of British productivity consider the Mullard plant at Blackburn where production is measured by the million pieces and productivity is unashamedly the goal.

It is a huge plant covering 46 acres and was established in a small way in 1938. Famous for its high volume valve production it is now busy on additional products following a slow run-down of valve production as solid state devices have become more widely used. But Mullard Blackburn still produces 27 million valves a year so don't imagine the valve is already dead.

In 1988 Philips finally dropped the Mullard name from its operating companies.

Click here for all our Mullard valve articles.

|