|

Recording in America by the vertical cut or hill and dale method.

Electrical transcriptions are recordings of complete entertainments, mostly sponsored advertising programmes, specially made for broadcasting. This term implies, as a rule, cutting on 16 inch discs at 33⅓ RPM and usually today the vertical or hill-and-dale method of recording is employed.

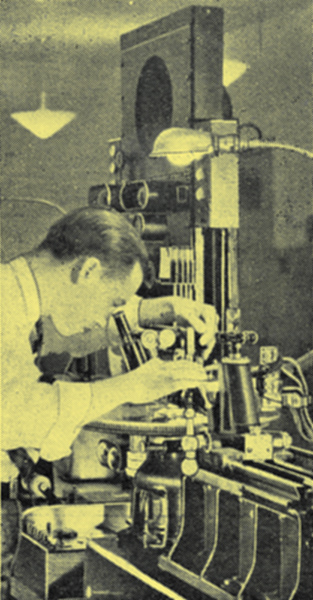

One of the several precision vertical recorders in the machine room of the World Broadcasting System in Chicago.

One of the several precision vertical recorders in the machine room of the World Broadcasting System in Chicago the engineer is examining the grooves on the wax through a microscope. Each side of these slow-speed discs has a playing-time of about 15 minutes and it is claimed that the vertical recording method permits accurate cutting up to at least 10 kHz.

Two members of the cast of 'Judy and Jane'.

In the second photograph two members of the cast of 'Judy and Jane', the oldest transcribed advertising programme radiated in America (this series has been broadcast since February, 1932), are seen reading their lines into a microphone in a studio of the WBS. The engineer in the foreground is manipulating one of the pick-ups on the record reproducer trolley, which enables sound effects to be mixed in on the recording channel.

After the wax blank has been cut it has to be processed. First, the blank is placed in a vacuum chamber, where for 20 minutes it undergoes electronic bombardment, or, as it is termed, cathode sputtering, i.e., a film of gold, a few millionths of an inch thick, is deposited on the wax surface, thus ensuring conduction for the electrolytic copper-plating process that follows. (This sputtering technique, originally introduced by Edison in 1900, replaces the old method of dusting the wax with graphite powder, which, being granular, contributes to surface-noise in the final pressing.) Now the gold-plated blank is suspended in an electrolytic bath, where it slowly acquires a copper coating. Then it receives a second plating and emerges with a thick copper layer grown on its surface.

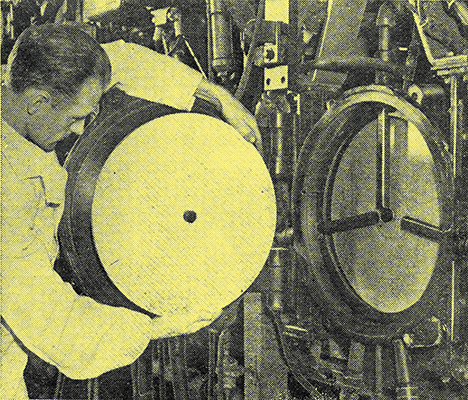

One type of plating equipment.

The illustration shows one type of plating equipment employed. Next, the copper master is carefully removed from the wax and trimmed, to be followed by chromium plating to prevent erosion. This copper master stamper is now placed in an hydraulic press with a 'biscuit' of plastic material and so the final pressing is produced. The recordings are pressed in 'vinylite' (a plastic used for dental plates and motor car steering wheels) or cellulose acetate, instead of the loaded shellac composition normally used for the commercial production of records in quantities.

|