|

The De Forest Audion was made with a tantalum filament. This filament tended to distort when hot and in extreme cases could bend to touch the grid and thus ruin the valve. McCandless introduced Audions with the mechanically more stable tungsten wire as a filament. The downside of using tungsten was that the emission of electrons was inferior to tantalum.

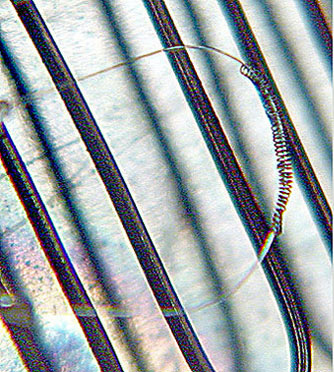

One of McCandless's customers Walter G Hudson suggested wrapping tantalum wire around the tungsten wire to get the benefit of both. The fine tantalum wire formed the emissive cathode and the tungsten wire provided the mechanical rigidity and the heating power.

As can be seen from the photographs the tungsten filament was threaded into a coil of fine tantalum wire.

Hudson patented the compound cathode in 1914 and later sold the patent to de Forest. Many thousands of Hudson filament Audions were made and used by the US military in 1914 and 1915. Examples were also held (possibly used) by the UK.

McCandless found the compound cathode tedious and expensive to make and Hudson did eventually supply finely divided tantalum in an organic binder paste to be applied to the tungsten filament. It was reported that in use black patches appeared in the envelope and it is possible this was a partial failure of the cathode material.

See Audion Amplifier.

A Hudson filament in a spherical Audion.

|